Can banana leaf protein increase cows’ milk production? And will piglets thrive on the whey side stream of protein extraction?

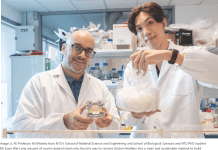

A green biorefinery that can transform leaves and other plant residues into a concentrated protein will soon go into operation at the BIO4Africa test site in Uganda. Designed to process up to 1000kg of feedstock an hour, the biorefinery holds game-changing potential for local smallholder farmers. If all goes to plan, the protein products will both generate a new source of income and improve yields from livestock farming.

BIO4Africa partner Grassa is the company behind the technology and is collaborating with Kabarole Research & Resource Center (KRC) to establish the Ugandan facility. As an agribusiness hub, KRC works closely with the smallholder farmer groups and cooperatives that will have access to the technology.

“We are really building a small factory,” says Wim van Doorn, project leader and environmental scientist at Grassa. “The objective is to make products that are easily transportable so farmers can get more value from their crops.”

Fresh local feedstocks

Based in the Netherlands, Grassa has already demonstrated the technology’s ability to extract high-quality protein from meadow grass. In Uganda, the plant will test a range of locally available feedstocks, including banana leaves.

“There are a lot of bananas in Uganda. Young leaves grow from the stem and are usually cut off and left on the soil. We already know from tests with a lab-scale biorefinery that banana leaves are processable and that they contain enough protein to make processing feasible.”

Mucuna beans, alfalfa and cassava leaves are other likely feedstocks for the production of new products that farmers can sell – green protein concentrate for chickens and fish, press cakes for cattle, goats, and sheep, and whey for piglet feed.

By raising the nutrient content of feed, all these biorefined products have the potential to improve results from livestock farming. According to van Doorn, initial feed trials with the press cake show that dairy cows produce up to 25% more milk. The addition of protein concentrates and whey to pig feed may also reduce mortality.

An essential requirement is that all feedstock is fresh, which is why the biorefinery must be close to the feedstock source.

Transfer to Ghana

A fresh feedstock is easy to come by all year round in Uganda’s very fertile climate. Later in the BIO4Africa project, the green biorefinery will be tested in Ghana – a country known for its short, rainy season and a long, very dry season. KRC will facilitate the technology transfer to the Ghana test site.

“The optimum biorefinery size may be different in Ghana, where fresh feedstock will only be available for a few months of the year. Here, the opportunity to produce storable animal feed could be a game-changer for cattle farmers, as it can ensure the feed supply during the dry season,” Van Doorn explains.

Grassa is documenting all findings from the trials. As Van Doorn says, it’s not just about technology. By the time BIO4Africa draws to a close, the goal is to have established a sustainable business model covering the whole value chain – from sourcing the feedstock to the biorefining of marketable products to recycling residual minerals back to farmland as fertilizers.

How does the green biorefinery work?

Grassa compares its biorefinery machine to a slow juicer. Mechanical pressing of leaves and other plant residues produces a press cake and juice, each containing half of the protein content in the predigested form. The addition of lactic acid bacteria to the juice draws out the protein, which is then dried into green protein concentrate powder.

The remaining liquid is whey, which contains sugars and minerals. The ambition is to concentrate the whey to make it easy to transport. It can then be used in animal feed, as a fertilizer or to make silage by adding it to the press cake.

Source:Bio4Africa